Exploring the Versatility of 82.51×63: Applications and Innovations

Understanding 82.51×63: Dimensions and Specifications

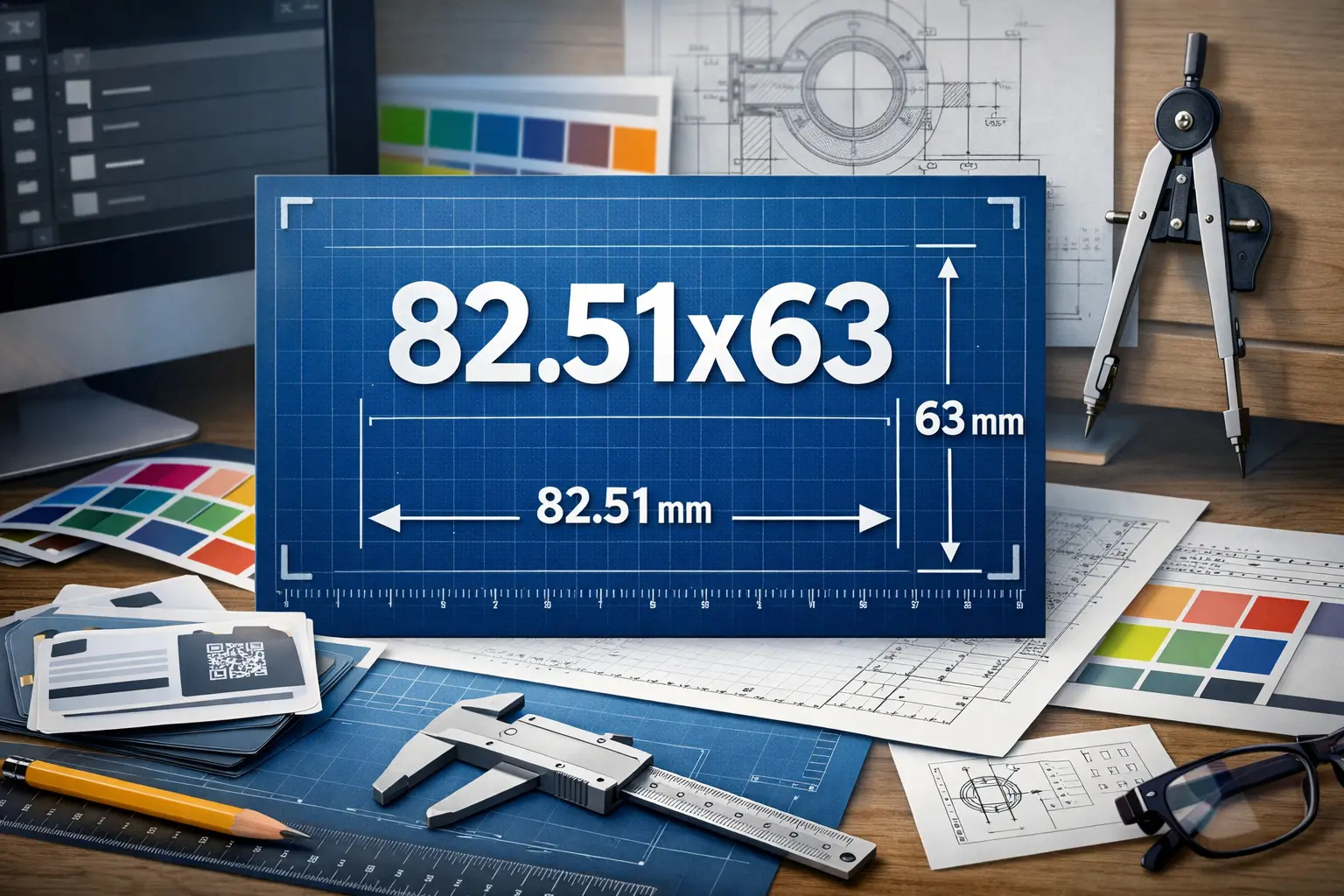

The dimensions 82.51×63 refer to a specific measurement that finds application in various sectors, including textiles, manufacturing, and design. To comprehend the significance of these numbers, one must consider that the first figure, 82.51, typically represents a longer dimension while the subsequent number, 63, denotes a shorter one. This combination may indicate a rectangular shape, such as a fabric roll or machinery component, where an aspect ratio plays a critical role in functionality.

In textile applications, for instance, the 82.51×63 dimension is used to determine the amount of material needed for specific projects such as upholstery, drapery, and garment making. The larger measurement of 82.51 can denote the width of a fabric roll, while 63 may signify its length or the repeat pattern of a design. Understanding these dimensions is essential for designers and manufacturers when calculating how much fabric is required and how to optimally layout patterns.

In the manufacturing realm, components designed with measurements such as 82.51×63 could have implications for compatibility with machinery or other elements. For example, parts with these dimensions might be standard for certain machinery designs, ensuring that they fit seamlessly with existing systems. Additionally, in industrial design, knowing the precise specifications of 82.51×63 can assist engineers and designers in prototyping and creating products that meet specific physical criteria.

Overall, the dimensions of 82.51×63 are more than mere numbers; they embody a vital part of how industries approach their products and solutions, streamlining processes and enhancing practical applications across varied sectors. Understanding these dimensions ensures that professionals can leverage them effectively in their respective fields.

The Applications of 82.51×63 in Various Industries

The dimensions of 82.51×63 have become pivotal in a myriad of industries, showcasing their versatility and practicality. In construction, for instance, these specific measurements are often utilized in the fabrication of building materials such as drywall and insulation panels. These standard sizes help streamline the construction process, allowing for efficient planning and installation. Moreover, the use of 82.51×63 in window and door frames ensures a perfect fit in standard openings, enhancing structural integrity and energy efficiency in residential and commercial buildings.

In the manufacturing sector, the dimensions play a critical role in creating components for machinery and electronics. Products that require precision engineering often leverage the 82.51×63 measurements to ensure compatibility and functionality. For example, in the automotive industry, various parts such as brackets and panels are manufactured adhering to these dimensions to maintain design consistency and performance reliability across different vehicle models.

Within the realm of art and design, the 82.51×63 dimensions are favorably adopted in modern art pieces, including canvases and sculptures. Artists select these dimensions to convey specific aesthetic principles while achieving balance and visual appeal in their work. By employing dimensions like 82.51×63, creators discover a harmonious way to present their artistic visions, enabling a wide range of interpretations and emotional responses.

Additionally, the versatility of the 82.51×63 dimensions extends to sectors such as packaging and textile design. Companies leverage these standard measurements to optimize space for shipping and storage, ensuring products are efficiently packed and presented. As industries continue to innovate, the applications of 82.51×63 are likely to expand further, reflecting their significance across various sectors.

Technological Innovations Related to 82.51×63

The 82.51×63 dimension has become increasingly relevant in various technological innovations, particularly in the realms of design and manufacturing. One of the key advancements is the integration of Computer-Aided Design (CAD) software, which allows engineers and designers to create highly accurate models that incorporate the 82.51×63 measurements. Notably, CAD tools streamline the process of prototyping, enabling designers to visualize and rectify design flaws before moving to production.

In addition to CAD, 3D printing technology has revolutionized how products are developed using the dimensions 82.51×63. With additive manufacturing, it is now possible to produce complex geometries and customized items that precisely conform to this size specification. This flexibility not only enhances the versatility of the design process but also significantly reduces material waste and production time, impacting industries ranging from aerospace to healthcare.

Moreover, the application of 82.51×63 in the realm of smart manufacturing has been noteworthy. The implementation of IoT (Internet of Things) devices in factories allows for real-time monitoring and optimization of production lines that rely on these dimensions. For example, sensors can provide feedback on machinery operating at 82.51×63 specifications, helping to uphold quality and efficiency standards.

As technology continues to evolve, we anticipate further innovations that will refine how the 82.51×63 measurements are applied across different sectors. Notably, advancements in artificial intelligence (AI) are paving the way for predictive modeling that integrates these dimensions, allowing manufacturers to anticipate and respond to market demands more effectively. The progression of such technologies highlights the dynamic nature of industrial design, demonstrating how the 82.51×63 dimension is not merely a measurement but a crucial element of innovative engineering solutions.

Conclusion: The Future of 82.51×63 in Design and Industry

The dimension of 82.51×63 represents more than just a set of numerical values; it symbolizes a future filled with innovative possibilities within design and industry. As various sectors begin to appreciate the significance of this specific measurement, the adaptability it offers becomes increasingly apparent. From product development to architectural design, integrating 82.51×63 into project specifications can lead to new levels of creativity and functionality.

Future trends indicate that industries will lean more towards customized solutions, where measurements such as 82.51×63 can optimize space and improve user engagement. This dimension can influence product aesthetics, ergonomics, and performance, thereby aligning with contemporary consumer demands for both form and function. Employing 82.51×63 can facilitate seamless integration into existing frameworks, ensuring that products are not only visually appealing but also maximally effective in their intended use.

Moreover, advancements in technology and manufacturing processes can enhance the application of 82.51×63. As 3D printing and precision engineering evolve, the ability to create custom components utilizing this measurement will likely become more accessible, paving the way for novel innovations in various fields, including robotics, furniture design, and automotive engineering. The significance of 82.51×63 will continue to grow, steering industries toward more efficient and sustainable practices.

In conclusion, understanding the versatility of 82.51×63 will equip designers and manufacturers with the insights necessary to push boundaries. As organizations adopt this dimension in their design processes, the potential for improved outcomes is vast. The future of 82.51×63 is bright, with numerous applications waiting to be explored, positioning it as a vital component in the evolving landscape of design and industry.